A Beginner's Guide to Interfacing

Whether you are a sewing enthusiast already or completely new to sewing, it is always exciting to start a new project. Being able to create something to your own specifications, design and taste that you know will be unique to you, is one of the joys of sewing. However, starting to use a new technique or work with a new fabric, can always be a little daunting - even for more experienced makers! So, if you always wanted to try using interfacing, but weren’t sure what interfacing to use or how to work with this material - we are here to help you!

To celebrate the launch of our new Vlieseline range of interfacing, we are delving into the essentials of this fantastic backing fabric, looking at everything you need to know to get started!

What is Interfacing?

Interfacing is a type of backing fabric that is applied to the back of your fabric and then sandwiched between the outer fabrics so it cannot be seen. Interfacing is used to create body, add strength and rigidity to your project. This backing fabric can be used across an entire item, such as a fabric tote bag, or on smaller parts of a project such as a waistband, shirt collar or jacket lapels. There is a whole range of different types of interfacing available, to complement every project and the specifications of different fabrics, as well as various weights and types of application to suit the purpose and strength of backing required for each task.

Which interfacing should I use?

Knowing which interfacing to use, can feel like a minefield as there are so many options, so let’s break it down to some key characteristics. As you become more familiar with using interfacing, you’ll find that the myriad of interfacing products will give you greater options for your projects and ensure successful results every time.

What is fusible and non-fusible interfacing?

Fusible interfacing is also commonly known as iron-on interfacing. It is by far the easiest type of interfacing to use and is perfect for anyone new to using interfacing as well as professional tailors and dressmakers alike. Fusible interfacing has fusible ‘glue’ on one side, which bonds to the back of your main fabric when the gentle heat from your iron is applied. The adhesive side is usually shiner with a rough texture, compared to the non-adhesive side.

Before you start, make sure you check the manufacturer’s instructions for the application method as these can vary across different types of interfacings. To apply the fusible interfacing to your fabric, start by placing your main fabric face down on the ironing board and giving this a light press to remove any creases. Next place the adhesive side of your interfacing on to the back of your fabric and cover with a cloth (in case any adhesive seeps through). Iron carefully according to the manufacturer’s heat instructions and gently press on the fabrics, rather than gliding as this will avoid any of the pieces shifting. If you are using light-weight interfacing you can use a piece the same size as your main fabric so it includes a seam allowance. However, it is important to note that if you are using a heavier weighted interfacing, to trim the piece to the stitching line to avoid adding any unnecessary and awkward bulk at the seams.

Non-Fusible interfacing is also referred to as sew-in interfacing fabric. It can be trickier to work with, so often beginners will prefer to opt for fusible backing, providing it works for their plans. However, some fabrics and projects will require a non-fusible interfacing, such as when the main fabric isn't suitable for ironing or when the item requires a softer finish, without the appearance of a backing fused to the fabric. Non-fusible interfacing is sewn between the layers of the main fabric, hence why it can be more challenging to work with. If you are fairly new to using this type of backing, practise with some fabric scraps and a small piece of interfacing first. Once you feel confident with your technique, you’ll be ready to tackle this next step of your project.

What weight of interfacing should I use?

Interfacings are available in light-weight through to medium, heavy and extra heavy weight options. The general rule is that you should select an interfacing that is slightly lighter in weight to your main fabric, otherwise the interfacing can dominate your fabric and create an unnatural structure to the item. We list the weight of our fabrics on our selling pages to help you select the right backing. You may find some items require two or more different weights of interfacing. A crossbody bag, for example, will have multiple pieces that need to function in various ways. The sides and base will need to be stronger and hold their shape so will require a medium or heavy weight backing, whereas a light-weight interfacing will work better for the flap to provide a lighter, more flexible finish.

What is woven and non-woven interfacing?

Simply put, woven interfacing appears to look like fabric - you’ll be able to see the weave and grain, however as an interfacing, it has a stronger, tougher feel. Woven interfacing typically fuses well with your main fabric and allows your fabric to drape and move naturally, albeit with added weight and thickness. Woven interfacing needs to be applied along the same grain as the main fabric, to ensure the fabrics fuse and drape properly.

Non-woven interfacing is made from compressed fibres and has no grain (similar to the appearance of felt), so it can be used in any direction. Lighter non-woven backings may have a thinner, wispy finish whereas the heavier weighted non-woven interfacings will have a stronger paper-like appearance.

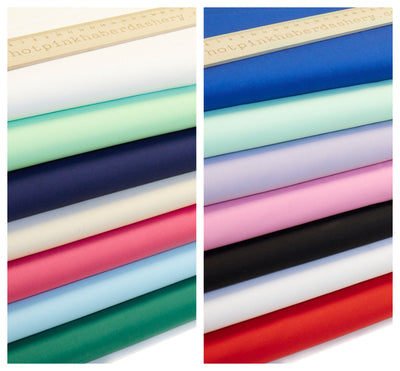

Our ever-expanding range of interfacings!

Our collection of interfacings start from just 99p a metre and, to complement our very popular value range, we have recently launched our new range of Vlieseline interfacings.

Who is Vlieseline?

Previously known as Vilene, Vlieseline is recognised as the professional's choice for interfacing and wadding product. Over the past 60 years, Vlieseline has become a globally recognised brand for high quality interfacing products. Vlieseline interfacing is suitable for everyone's projects, whether you are a sewing enthusiast or professional tailor or dressmaker.

Altogether our range of interfacings provides a great wealth of options to meet the desired look, feel and functionality of your projects. Make sure to check the instructions and guidelines on your pattern for the recommended type of interfacing to use. Our product listings include all the details from the manufacturer to help you make the right selection. From light-weight to heavy-weight Vlieseline interfacings, there are additional options to choose from to suit every project, as well as complementing the weight & texture of your chosen fabric.

We wish you well with your next project! We always love seeing our customer’s projects, so please feel free to share your results with us on our Instagram page.

Leave a comment